Brief Introduction

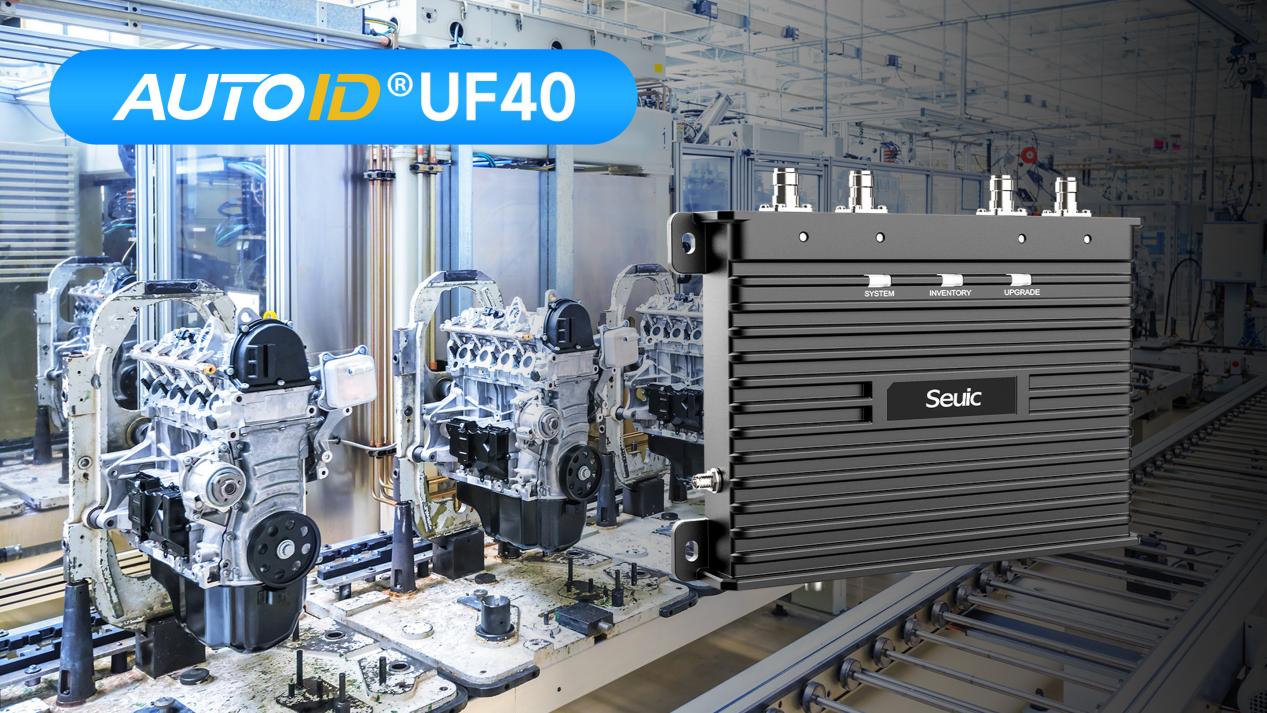

In the wave of Industry 4.0 and smart manufacturing, the Manufacturing Execution System (MES), as the central nervous system connecting the planning layer and the control layer, directly determines a factory's agility and transparency through its effectiveness. However, the performance bottleneck of MES systems often lies not in the software itself, but in the real-time nature, accuracy, and automation level of underlying data. How to achieve non-intrusive, accurate data collection for materials, work-in-process, tools, and personnel? The SEUIC UF40 Fixed RFID Reader is the key hardware cornerstone to solve this problem. It translates the physical flow of production in real time and accurately into traceable information flow in the digital world.

This article will delve into how the SEUIC UF40 Fixed RFID Reader, with its excellent performance, is deeply embedded in MES systems, driving production management towards leanness and intelligence.

1. MES System Data Challenges and UF40's Solution

Traditional MES data collection relies on manual scanning or data entry, suffering from inherent shortcomings such as low efficiency, error-proneness, delays, and difficulty in achieving full-process traceability. Especially in core links like material distribution, process flow, production line balancing, and quality traceability, information black holes lead to delayed decision-making.

The introduction of the SEUIC UF40 Fixed RFID Reader provides a revolutionary solution: through non-contact, batch, penetrating reading of RFID tags attached to carriers, pallets, work-in-process, or tools, it enables 24/7 uninterrupted automated data collection. It acts like "intelligent eyes" deployed at key stations, production line entrances, and warehouse passages, ensuring that every movement of every item is perceived and recorded in real time by the MES system, providing an indisputable data foundation for lean production and full-process traceability.

2. UF40 Core Features: Reliable Performance Born for Harsh Industrial Environments

As a fixed data collection node on the production line, the UF40 must possess extremely high reliability and environmental adaptability. The design of the SEUIC UF40 fully considers the challenges of industrial scenarios:

1) Industrial-Grade Rugged Design, Fearless of Complex Environments

The UF40 uses a high-strength industrial housing with excellent dustproof, waterproof, impact resistance, and anti-electromagnetic interference capabilities. It can operate stably in harsh workshop environments with vibration, oil stains, and dust, ensuring the continuous reliability of the data collection link.

2) High Power and Sensitive Antenna, Ensuring Stable Reading Distance and Coverage

Equipped with a high-performance RFID core module and optimized antenna design, it provides stable and adjustable reading distance (configurable according to the scenario, typically up to 0-8 meters or more). This ensures a near-100% read rate within the set passage or area, regardless of tag orientation or speed, eliminating missed reads.

3) High-Speed Anti-Collision Algorithm, Handling Dense Flow

During peak production hours, materials and vehicles pass through intensively. The UF40 adopts an advanced anti-collision algorithm, capable of identifying hundreds of electronic tags accurately per second, meeting the data collection needs under high-cycle, high-flow production conditions, and avoiding data congestion and loss.

3. Key Application Scenarios and Value Realization of UF40 in MES

The integration of UF40 and MES can create significant value in the following core scenarios:

Scenario 1: Material Warehousing and Intelligent Distribution

Deploy UF40 at warehouse entrances/exits and shelf areas. When material pallets with RFID tags enter or exit, the system automatically performs batch recording for inbound, outbound, and relocation, with inventory data synchronized to the MES in real time, achieving nearly 100% accuracy. Combined with AGVs or distribution vehicles, it enables automatic material identification and on-demand precise distribution to line-side storage, greatly improving warehouse logistics efficiency and transparency.

Scenario 2: Real-Time Work-in-Process (WIP) Tracking and Error Prevention on Production Lines

Install UF40 at each key workstation. When carriers or carts carrying WIP with RFID tags enter the station, the reader automatically identifies the product identity. The MES system immediately retrieves the corresponding process files, work instructions, and automatically checks the Bill of Materials (BOM) for error prevention. Simultaneously, it automatically reports process start/end times, providing accurate man-hour analysis and production line balancing data for MES.

Scenario 3: Full-Process Quality Traceability and Asset Management

From raw material storage to finished product shipment, product identity information (serial numbers, batch numbers, etc.) is bound to key quality data (inspection results, operator, timestamp) throughout the process in the MES. Through automatic collection by UF40 at key nodes, any product can achieve second-level forward and backward traceability, greatly improving the speed of troubleshooting quality issues and the accuracy of recalls. Furthermore, managing high-value tools, fixtures, and containers with RFID enables asset localization, utilization statistics, and scheduled maintenance reminders.

Scenario 4: Support for Flexible Manufacturing and Mixed-Line Production

Facing the demand for multi-variety, small-batch flexible production, the UF40 can automatically identify carriers of different product models, guiding the MES system to quickly switch production orders, process parameters, and test programs, reducing changeover time, and enhancing the flexibility and response speed of the production system.

4. Deployment and Integration: Maximizing the Effectiveness of UF40

l Scientific Point Planning: Based on factors such as read/write distance, tag type, object speed, and metal environment interference, conduct professional point design and testing at key control points of the production line (e.g., entrances, exits, buffer zones, and workstations).

l Tag Selection and Attachment Solution: For different carriers (metal, plastic, liquid) and process environments (high temperature, cleaning), select appropriate RFID tags (anti-metal tags, high-temperature tags, etc.) and reliable attachment methods to ensure tag readability throughout its lifecycle.

l Seamless MES System Integration: The UF40 provides rich industrial interfaces (such as Ethernet ports, I/O ports) and a standard Software Development Kit (SDK), enabling easy integration with mainstream MES, WMS, or SCADA systems for smooth data upload and reliable command reception.

In the construction of digital twins for smart manufacturing, a reliable data perception layer is the starting point for all optimization. The SEUIC UF40 Fixed RFID Reader, with its industrial-grade reliability, exceptional read/write performance, and deep integration capability with MES systems, successfully transforms traditional production "black boxes" reliant on manual intervention into intelligent, transparent "white boxes" characterized by data transparency, controllable processes, and intelligent decision-making. It serves not only as the "data granary" for MES systems but also as a key engine driving enterprises towards production visualization, refined management, end-to-end traceability, and intelligent operations.

For years, SEUIC has focused on the research and development of products such as handheld PDAs, RFID readers, fixed scanners, and industrial barcode scanners. Leveraging extensive design experience in the industrial-grade 4G/5G terminal field and relying on highly reliable product capabilities and efficient services, our products have been widely used in manufacturing, retail e-commerce, logistics and express delivery, healthcare, and public utilities.

- 2026 RFID Logistics Parcel Tracking Integrated Solution2026-02-12

- Complete Guide to IP Ratings for Industrial Mobile Computers: Selecting the Most Reliable Rugged Devices for Harsh Environments2026-02-12

- IP68 Industrial RFID Reader Selection Guide - Equipment for Harsh Environments2026-02-12

- Medical Mobile Device Success Case: How to Improve Hospital Efficiency and Safety2026-02-12

- Driving Intelligent Upgrades in Logistics Warehousing: CRUISE2 5G Rugged Mobile Computer Solves Sorting Efficiency Challenges2026-02-11