Brief Introduction

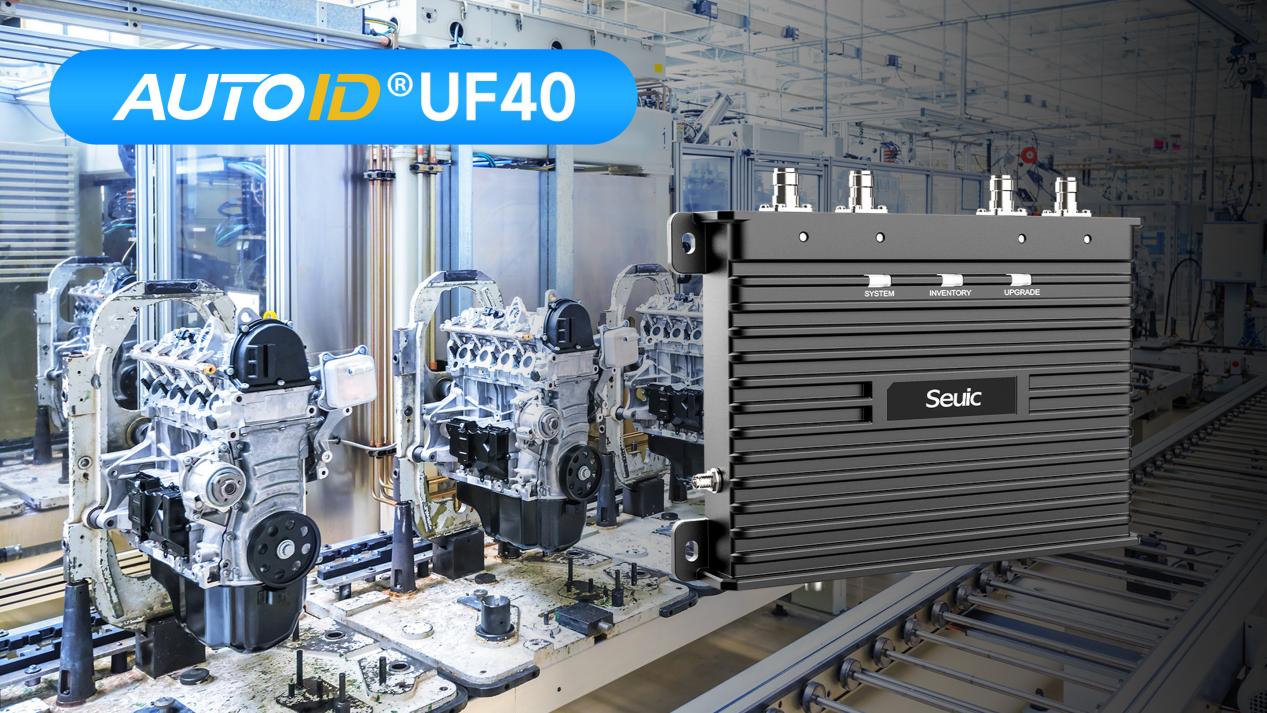

In the digital transformation of manufacturing, building a full-chain quality traceability system that spans from raw materials and production to warehousing and sales is core to achieving lean management, meeting compliance requirements, and enhancing brand reputation. However, traditional traceability methods relying on manual records or barcode scanning suffer from inherent drawbacks like low efficiency, error-proneness, and broken data chains. The SEUIC UF40 RFID reader, with its deeply integrated AI intelligence, high-speed group reading capability of up to 1300 reads/second, and convenient industrial deployment, assigns a precise "digital ID" to each product. It achieves real-time, accurate, automatic binding of the product's physical flow with its information data flow, building a solid and reliable foundation for quality traceability.

1. The Dilemma of Quality Traceability: Why are Data and Products Always "Disconnected"?

Ideal full-chain traceability requires the ability to quickly and accurately answer "Where did the product come from, where is it now, and where has it been?" at any stage. But bottlenecks are often encountered in practice:

Low Information Capture Efficiency: Manual entry or scanning items one by one creates efficiency bottlenecks at stages like raw material receiving, production line transfer, and finished goods shipping, and is prone to human error.

Difficulty Achieving Batch Operations: Inability to quickly and simultaneously identify entire pallets or cartons forces case-opening operations, damaging packaging and reducing efficiency.

Poor Environmental Adaptability: Barcodes are easily soiled and become unreadable in industrial environments with oil, dust, or outdoor conditions.

Non-real-time Data Association: Production status, process parameters, and quality data cannot be associated with specific product items in real-time automatically, creating "information silos."

These issues cause breakpoints in the traceability chain. Once a quality problem occurs, it becomes difficult to quickly and accurately identify the responsible link and batch, leading to significant losses.

2. SEUIC UF40: Reshaping the Traceability Chain with AI and UHF RFID Technology

The SEUIC UF40 fixed reader integrates advanced AI capabilities and excellent RFID performance, providing a systematic solution to the above pain points.

2.1 AI Intelligence Empowerment Makes the Traceability System "Think"

Intelligent Self-Networking & Parameter Tuning: The UF40 supports intelligent self-networking, automatically optimizing network parameters, significantly reducing debugging time and complexity during multi-reader collaborative deployment.

Accurate Static/Dynamic Tag Distinction: Using AI algorithms, it can intelligently identify and distinguish stationary inventory tags from moving operational tags, effectively preventing misreads and cross-reads in complex scenarios, ensuring data accuracy.

2.2 Outstanding RFID Performance Ensures 100% Data Capture

Ultra-Fast Group Reading: Utilizing the high-performance Impinj E710 module and proprietary anti-collision algorithms, it achieves a maximum group read speed of 1300 tags/second, enabling instant batch inventory of pallets and cartons.

Long-Range Stable Reading: Under standard configuration, the read distance for tags exceeds 10 meters, and the write distance exceeds 5 meters, meeting various long-distance capture needs from warehouse aisles to production line gateways.

Precise Power Control: Adjustable output power from 1-33dBm with 1dB step precision allows precise control of the read/write zone to avoid interference.

2.3 Easy and Rapid Deployment, Seamless Integration into Industrial Sites

Flexible Power Supply & Integration: Supports PoE (Power over Ethernet) and 12-48VDC wide-voltage DC power supply for simplified wiring; built-in relays and multi-channel isolated GPIO allow direct connection to field indicators, alarms, or PLCs for linked control.

Robust Connectivity & Rugged Durability: Offers multiple communication methods including Gigabit Ethernet, RS232, Wi-Fi (dual-band), and 4G (optional). Rated IP54 for protection, with an operating temperature range of -20°C to +60°C, suitable for harsh industrial environments.

3. Core Application Scenarios of the UF40 in Full-Chain Traceability

Raw Material/Component Receiving and Binding: Deploy the UF40 at the warehouse receiving dock. When forklifts carrying material pallets with RFID tags pass by, it instantly reads all material information and automatically binds it to the purchase order, achieving accurate receiving.

Production Line WIP Tracking: Install the UF40 at key workstations to automatically capture RFID tags on product carriers (e.g., jigs, pallets), binding processing data, operator, equipment parameters, and timestamps in real-time to form a complete production history.

Finished Product Packaging & Outbound Verification: At the end of the packaging line, the UF40 automatically reads the tag on each product to be boxed, associating it with the carton tag, achieving "carton-item" relationship binding. During shipping, it quickly verifies if the loaded goods match the shipment order.

After-sales & Recall Management: When a product quality issue arises, the unique RFID identifier enables reverse traceability to the specific production batch, raw material batch, and even the production line and team, facilitating precise recalls and root cause analysis.

4. Deployment Value: From "Traceable" to "Intelligent Traceability"

Accurate, Uninterrupted Data: Achieves item-level, fully automated, real-time data capture, ensuring the traceability chain is 100% complete and trustworthy.

Leap in Operational Efficiency: Batch, non-contact identification increases data capture efficiency at each step by tens of times, reducing manual input.

Proactive Quality Control: Real-time binding of production data enables early warning and interception of issues during the manufacturing process, reducing quality costs.

Powerful Decision Support: Aggregated full-chain data provides the foundation for optimizing processes, precise production scheduling, and intelligent supply chains.

Founded in 2002, SEUIC Technologies Co., Ltd. has been committed to grasping core technologies, enhancing technological innovation, providing excellent self-owned brand products, including mobile computers, RFID readers, tablets, barcode scanners and fixed readers. With highly reliable products and efficient services, our products have been widely used in manufacturing, retail, logistics & transportation, healthcare and other industries. We provide frontline workers more durable real-time data collection tools, helping you do more thereby to catapult your productivity to the next level.

- The Efficient Choice for Logistics Sorting: Professional Recommendation and In-Depth Analysis of the CRUISE2 5G Rugged Mobile Computer2026-01-28

- Difficulties with Clothing Store Return Verification? AUTOID UTouch 2-S RFID Handheld Terminal Enables Second-Level Verification2026-01-28

- AI Empowerment: How the UF40 RFID Reader Achieves 1300 Reads/Second Accurate Quality Traceability?2026-01-28

- The Challenge of Reading DPM Codes on PCB Boards: SEUIC X4 AI Industrial Reader's Solution2026-01-28

- Low Read Rate for Lithium Battery Aluminum Plastic Film Codes? SEUIC X4 AI Reader Achieves 99.99% Breakthrough2026-01-26