Brief Introduction

In modern enterprise operations, RFID asset management is becoming a key technology for enhancing operational efficiency. Traditional asset inventory methods are inefficient, not only consuming significant human resources but also frequently suffering from data inaccuracies, which severely impact the quality of enterprise decision-making. Now, the emergence of Seuic's AUTOID UTouch 2-S RFID reader has fundamentally changed this situation. Through innovative mobile inventory technology, it brings unprecedented efficiency improvements to enterprises.

1. In-Depth Analysis of Pain Points in Traditional Asset Inventory

In today's fast-paced business environment, inefficient asset management processes have become a major obstacle to enterprise development. This is specifically reflected in the following four aspects:

1) Low Efficiency

Traditional inventory counting relies on manual, item-by-item barcode scanning. Inventory counting for a medium-sized warehouse often takes several days, severely encroaching on normal operating time and causing operational stagnation. This inefficient counting method can no longer meet the demands of modern enterprises.

2) High Work Intensity

Employees need to repeatedly bend over and look up to find barcodes, resulting in significant physical exertion. The monotonous workflow easily leads to fatigue, which in turn causes operational errors, affecting the accuracy of inventory data.

3) High Error Rate

Issues such as missed scans, duplicate scans, or unreadable damaged barcodes lead to persistently high rates of discrepancy between book records and physical counts. Low data credibility makes it difficult for enterprise management to make accurate decisions.

4) Information Lag

Long inventory cycles cause serious data delays. Managers cannot grasp the location and status of assets in real-time, always remaining in a reactive state.

2. Technological Breakthrough: Redefining the Asset Inventory Model

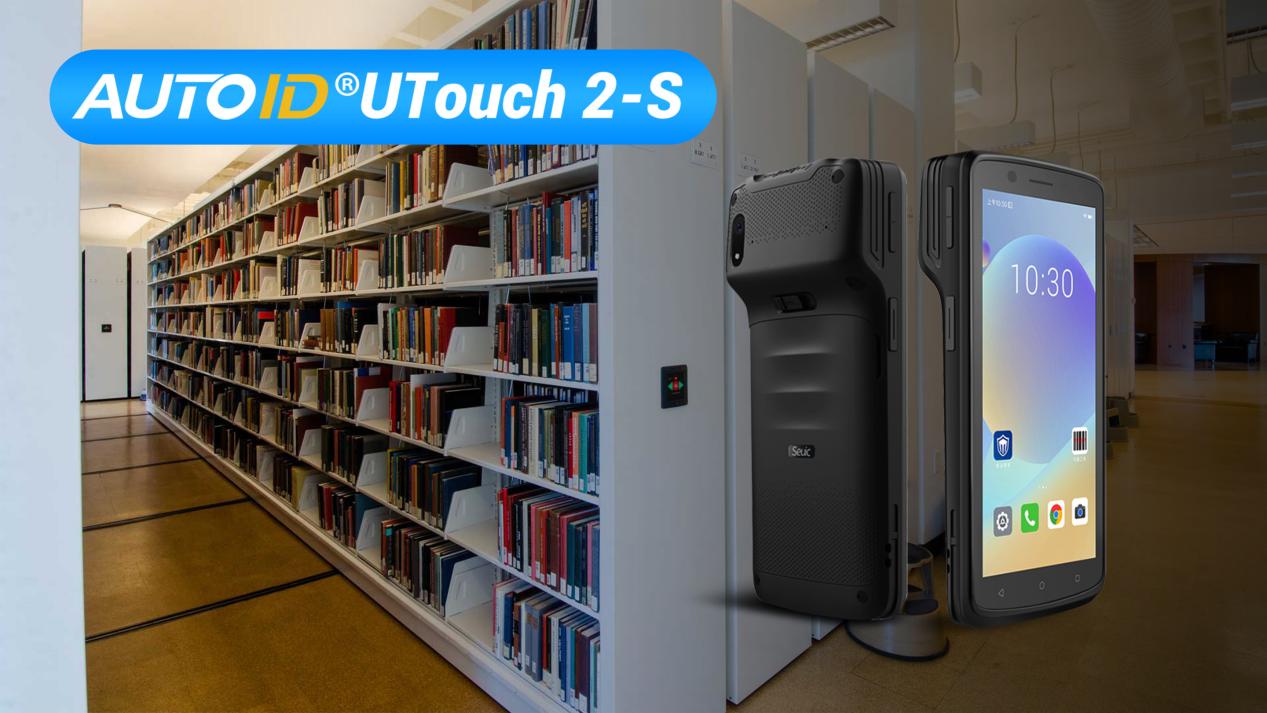

Seuic's AUTOID UTouch 2-S RFID Reader achieves a fundamental transformation in asset management models through technological innovation. This device is designed for RFID equipment inspection and possesses the following outstanding features:

1) Dual-Mode Reading Technology

l Conventional Reading Mode (0-6 meters): While the inventory operator walks through the aisle, the device can read asset tags on shelves in batches from a long distance.

l Vertical Reading Mode (0-3 meters): Achieves precise focused identification for densely placed assets.

This dual-mode design ensures dead-angle-free coverage during the inventory process, greatly improving the execution efficiency of the RFID handheld terminal warehouse counting solution.

2) High-Speed Processing Capability

Equipped with the latest Impinj module, it achieves an ultra-fast batch read speed of 700 reads/second. Powerful anti-collision algorithms ensure batch reading even during rapid movement, providing the technical foundation for "inventory while walking."

3) Precise Power Control

Precise step power control from 1-30dBm allows the device to adapt to various complex environments. Users can flexibly adjust read/write parameters based on factors like metal shelf density and asset distribution, ensuring reading stability and accuracy.

3. Professional-Grade Mobile Inventory Device Characteristics

The AUTOID UTouch 2-S is optimally designed for mobile inventory scenarios, making it an ideal core device for UHF RFID reader asset inspection systems:

1) Lightweight and Rugged Design

The device weighs only 325g. Combined with an ergonomic anti-slip texture design, it remains comfortable even during prolonged handheld operation. With an IP68 protection rating and 1.8-meter drop resistance, it ensures stable operation even in harsh environments.

2) Long-Lasting Battery Life

A 5000mAh high-capacity battery supports 12 hours of continuous operation, sufficient for all-day inventory tasks in large warehouses without needing mid-task charging, effectively guaranteeing work efficiency.

3) Multi-Function Data Collection

In addition to excellent RFID reading functionality, the device also integrates top-tier barcode scanning capability. For traditional assets not yet tagged with RFID, quick supplemental scanning can be performed, ensuring no omissions during inventory.

4. Typical Application Scenarios

1) Warehouse Inventory Management

In large warehouses, operators only need to walk once through the shelf aisles to complete the stock count for the entire area. This RFID inventory counting solution reduces inventory time from several days to a few hours, significantly improving operational efficiency.

2) Library Archive Management

In library scenarios, while the librarian walks along the shelves, the device can quickly read information from all books and archives. This non-contact inventory method avoids damage to materials caused by traditional counting methods while increasing work efficiency.

3) Manufacturing Equipment Inspection

In the workshops of large manufacturing enterprises, the RFID equipment inspection system can simultaneously complete the inventory and status verification of all equipment during routine inspection rounds. This integrated operational mode effectively saves human resources.

With the continuous development of Internet of Things (IoT) technology, RFID asset management systems will become more intelligent and integrated. As a leading product in RFID handheld terminal warehouse counting solutions, Seuic's AUTOID UTouch 2-S will continue to drive innovation in enterprise asset management models, assisting enterprises in their digital transformation.

- HS305DP Industrial Scanner Solves Barcode Scanning Challenges in Lithium Battery Module Assembly2026-03-04

- Solving the Challenge of Logistics Tracking: How Does the CRUISE2 5G Achieve Second-Level Synchronization of Package Information?2026-03-04

- Hotel Linen Management Innovation: AUTOID UTouch 2-S RFID Reader Efficient Control Guide2026-03-04

- Inventory Inaccuracy and Frequent Stockouts? The SEUIC AUTOID UTouch 2-S RFID Reader Ensures 100% Accuracy2026-03-03

- Solving the Challenges of Large-Scale Warehouse RFID Deployment2026-03-02