Brief Introduction

Customer Background

This global fast-food chain is known for more than just its burgers and fries — it's a benchmark in operational standardization and efficiency. With stores in nearly every corner of the world, the brand has built its reputation on consistency, food safety, and the ability to evolve through digital innovation.

As customer expectations shift and menus expand, the company needed a smarter way to manage ingredient lifecycles and ensure nothing slips through the cracks.

Challenges Faced

Despite its scale, several core store-level processes were holding the team back:

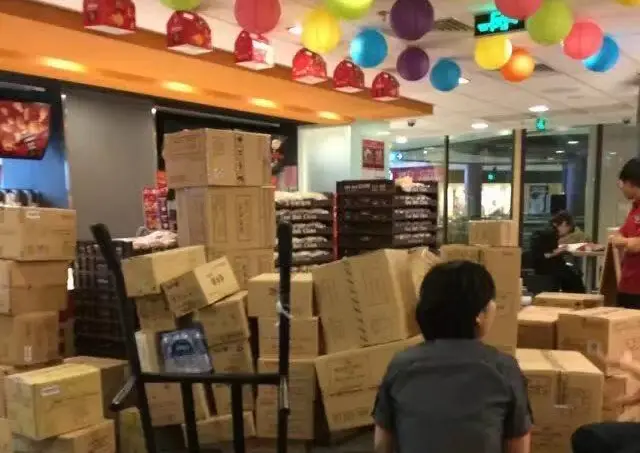

- Receiving Was Manual and Inaccurate: Stores previously used paper-based delivery notes. Staff often focused on verifying quantities, not item details, leading to frequent misdeliveries. Missing or incorrect ingredients disrupted workflows, caused food shortages, and directly affected sales.

- Inventory Checks Took Too Long: Daily and shift-based stock checks relied on paper and pen. Without dedicated inventory staff, frontline workers had to take time away from customer service — often during rush hours — resulting in both service delays and inconsistent stock records.

- Shelf Life Was Hard to Track: Ingredients with short shelf lives, such as fresh produce, dairy, and frozen items, were tracked manually. Expiry dates were handwritten or mentally noted, increasing the risk of expired items being used. Limited training and high staff turnover only worsened the problem.

Seuic's Integrated RFID & Barcode Solution

Seuic designed a comprehensive in-store digitization solution that combined cutting-edge hardware with backend integration, transforming ingredient and inventory workflows at the ground level.

1. RFID-Powered Ingredient Management

Each item is tagged at the ingredient level, allowing store staff to track its full lifecycle — from receiving, to thawing, to usage. Seuic's AUTOID UM3 RFID reader instantly scan multiple items in seconds, with expiry data and usage status displayed on-screen in real time.

2. Smart Receiving & Inventory

Deliveries can be scanned quickly using RFID handhelds, with visual confirmation of product types and quantities. Barcode scanning modules are used for products not yet RFID-tagged. This enables mixed-mode operations, ideal for gradual rollout.

3. Backend System Integration

All data — from stock levels to expiry tracking — flows into the brand's centralized platform (MDM). The system is future-ready, designed to expand into kitchen tablets, point-of-sale systems, and staff training tools.

Tangible Results & Benefits

The results went beyond just time savings. With Seuic's completed solution in place, this global brand saw a measurable shift in day-to-day operations:

✅ Digitized Workflow = Less Internal Friction

Manual paperwork and redundant communication were reduced by up to 30%, enabling smoother collaboration across store teams.

✅ Training Time Cut by Half

The user-friendly interface and visual workflows made onboarding faster and easier, with training time reduced by 50% — even for part-time or seasonal workers.

✅ Expiry Alerts Prevent Waste and Risk

Automated notifications ensured timely use or removal of products nearing expiry. The improved visibility enabled 20% faster execution of promotions or ingredient transfers between stores.

✅ Live Inventory Dashboard

Managers now have a real-time view of stock status. Inventory accuracy and checking speed improved by 35%, allowing proactive planning instead of reactive problem-solving.

Conclusion

By embracing Seuic's RFID and barcode solution, this global fast-food leader turned manual bottlenecks into digital advantages. From receiving ingredients to managing expiry and tracking inventory, the result is a faster, smarter, and more reliable store operation — ensuring every meal is served fresh, every shift runs smoothly, and every team member is empowered to do their best work.- Hotel Operations Go Smart: RFID at Fairfield by Marriott2025-10-29

- Smart Tech Behind the Counter: Driving Digital Transformation in Food Retail2025-06-13

- How a Leading Coffee Chain Digitized Store Operations with RFID2025-05-14

- Unlocking Efficiency at China Eastern Airlines with RFID Technology2024-10-25

- How RFID Technology Boosts Textile Manufacturing Efficiency2024-10-24